I posted this at Super Soaker Central about 2 weeks ago and figure that I ought to post this here for more comments.

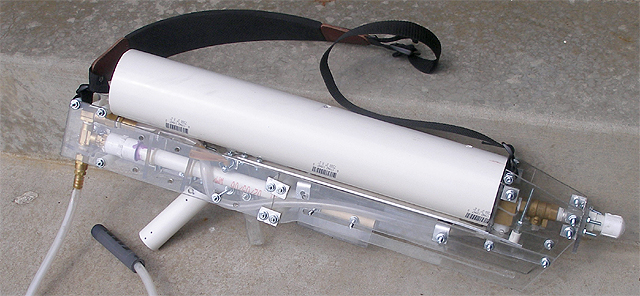

I've labeled this gun Riptide DR-4. It's a cylindrical CPS water gun with a trigger, tracked pump, and casing.

At the moment, the gun has a single tube of later rubber tubing to make the CPS bladder, but upgrades can happen if I want; though I don't right now.

The casing is 1/4" thick polycarbonate. I took some of the pictures below before I took the plastic casings paper coating off and before I replaced the grip. The gun's final state is as pictured above--clear and transparent.

The gun compares well to the CPS 3000: Both are 28 inches long; both have tracked pumps; both need a backpack reservoir. But my gun weights 7 pounds empty.

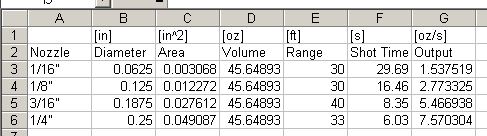

Let's look at my gun's preliminary performance tests:

This data is from tests I did this morning. The gun under-performs in these tests, because the new CPS bladder twisted and bent (click for a picture), decreasing the pressure applied to the water and decreasing performance. Still, a cubic approximation of the best nozzle size predicts that a 7/32 inch nozzle produces 43 feet in range, so I'll have to try out that later. To fix the problem, I will flip the bladder around or replace it entirely; it's only a problem with the rubber bladder itself, making it very fixable.

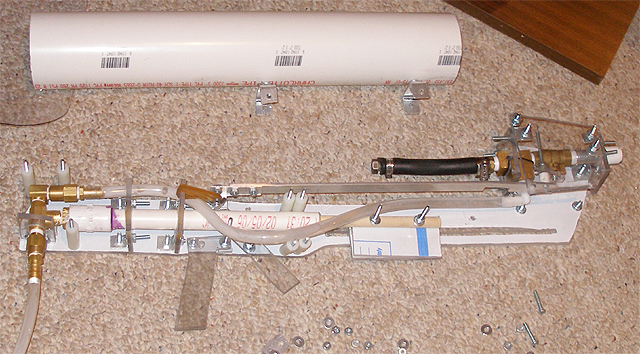

Internally, the gun is simple:

It pumps 45 mL or 1.5 oz with each stroke. I put all the check valves at the gun's pump end, where stock soakers also place them. This placement balanced the gun well.

All parts are brass; brass saved space but added weight. PVC composes only one part, the pump.

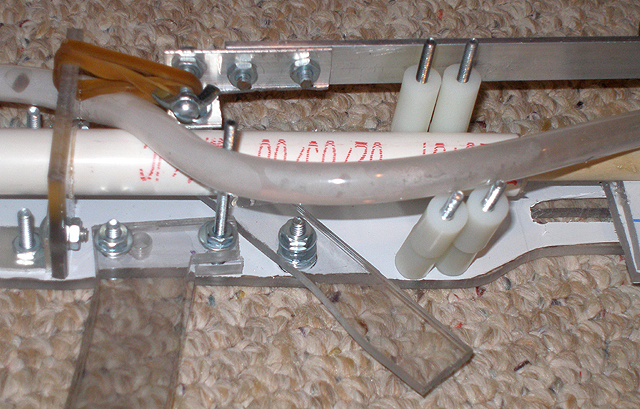

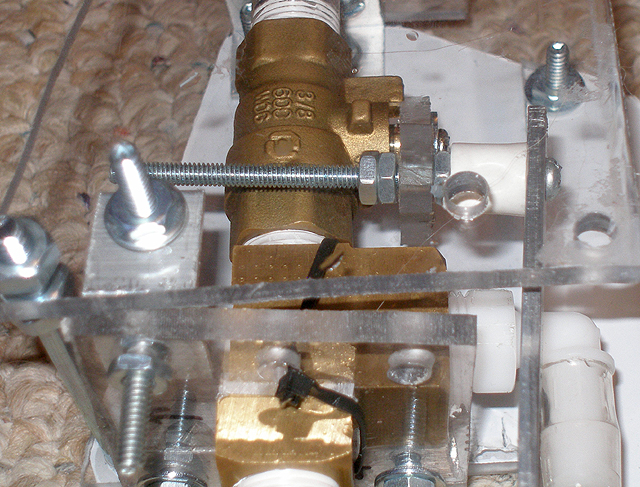

I designed an original trigger system: a rotary trigger. Most triggers are linear triggers--they travel in a straight line--but I chose a rotary trigger because it offered more displacement (change in position) in a smaller size. The ball valve I used needed around 1 1/2" inches of displacement to fully open; the designed pressed me for space in this region, so I let the trigger's path arc to get more displacement.

Two rubber bands folded onto each other return the trigger and valve a closed position. The user feels little resistance when pulling the trigger because the trigger acts as a torque arm, reducing the force you need to pull the trigger the farther out you pull it.

Such a simple system works well. This video shows that you can pulse shots with ease.

The valve is a 3/8" brass ball valve. The trigger pushes an aluminum beam, which pushes the firing valve's arm, opening the valve and shooting water. The valve closes when the rubber bands pull back the aluminum beam and close the valve.

I made a video of several trigger cycles to demonstrate this.