Guides and discussions about building water blasters and other water warfare devices such as water balloon launchers.

-

teamfear

- Posts: 228

- Joined: Sun Jun 29, 2008 2:35 pm

Post

by teamfear » Sat May 30, 2009 8:46 am

I am trying to create a pull valve that can use a conventional trigger on a homemade. I am currently designing my own type of APH and I would like it to be able to utilize a trigger of this sort.

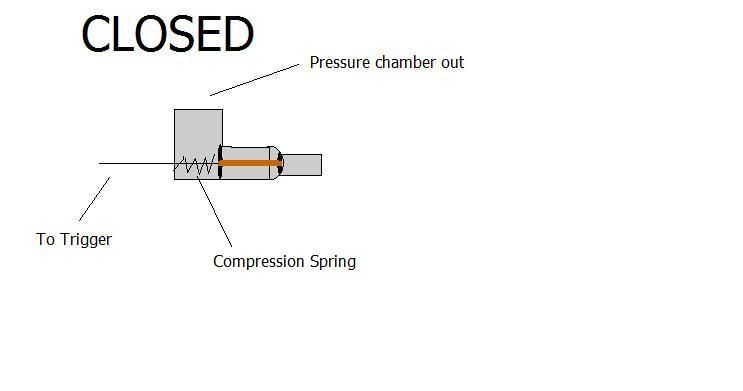

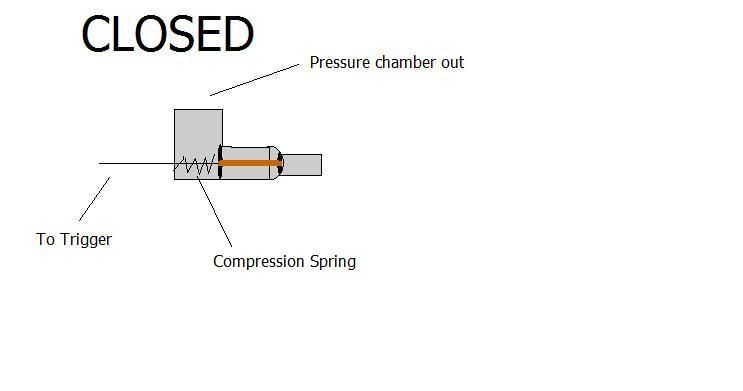

Here is the valve Closed:

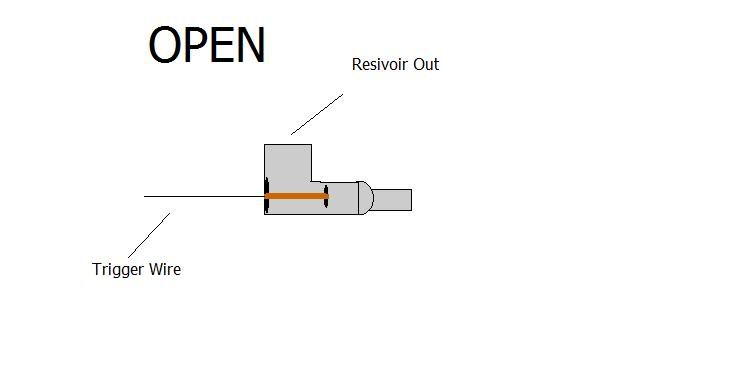

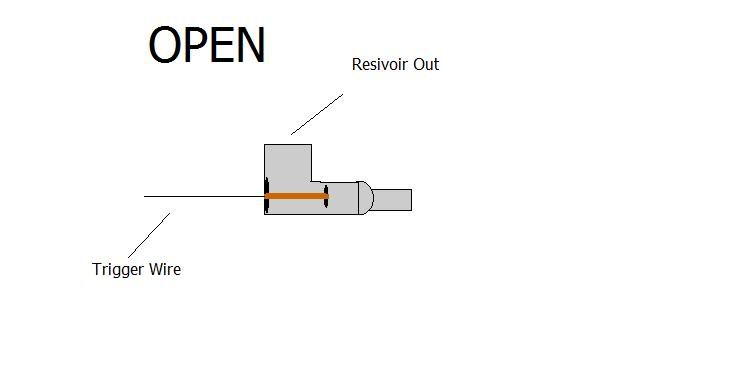

Here is the valve Open:

It would attach to the chamber of the gun from the point listed on the pictures. The Wire would go to a trigger and the spring would return the trigger to its original position. I wanted to use a homemade valve instead of a ball valve for my homemade because as observed in the DR-3 it is hard to get stock ball valves to close using a spring. My design would be wood and plastic and lightweight In the nozzle there would be a perfect spot to put straws to laminates the stream.

-

emperor_james

- Posts: 177

- Joined: Thu Mar 24, 2005 6:21 pm

- Location: Unites States

Post

by emperor_james » Sat May 30, 2009 9:42 am

How do you plan on building this, it seems like it would be tricky. In your current design how would you get the trigger wire outside the piping without creating a leak. I guess the main challenge for the whole thing would just be engineering the thing small enough.

ownage

-

teamfear

- Posts: 228

- Joined: Sun Jun 29, 2008 2:35 pm

Post

by teamfear » Sat May 30, 2009 10:42 am

Well i would need to get my hands on some sub 1" pvc. I was thinking of some sort of rubber seal wrapped tightly around the wire on the inside and outside.

-

Silence

- Posts: 339

- Joined: Sat Apr 21, 2007 3:01 pm

- Location: Virginia

Post

by Silence » Sat May 30, 2009 12:24 pm

You can't use a wire there because it has no compressive strength – only tensile strength. A rod would work better here because you can push the other way from the outside and close the valve again.

I'd just use an O-ring sliding in 1/2" PVC.

Why do you have two seals right now?

-

teamfear

- Posts: 228

- Joined: Sun Jun 29, 2008 2:35 pm

Post

by teamfear » Sat May 30, 2009 1:43 pm

I have the two seals because when pulled the larger seal would help seal the whole where the wire would be. It would also determine how much water flows through.There is a spring inside to return the wire to its normal position. I mean for the wire to be linked directly to the trigger. I don't quite get why wire wouldn't work for linking the valve to the trigger if I have a spring included.

-

Silence

- Posts: 339

- Joined: Sat Apr 21, 2007 3:01 pm

- Location: Virginia

Post

by Silence » Sat May 30, 2009 10:10 pm

If the larger seal only does its job when the valve is completely open, what seals that hole the rest of the time? And if the valve is sealed the rest of the time, why does it need extra sealing power when open?

The spring isn't pictured, so I thought it would be outside the valve. Sorry. Anyway, it looks like you've got that part covered.

-

teamfear

- Posts: 228

- Joined: Sun Jun 29, 2008 2:35 pm

Post

by teamfear » Sun May 31, 2009 12:40 pm

So you think I only need one seal. I could glue some rubber with a hole in it to the inside and outside of the valve so the wire can pass through without leaking.

Users browsing this forum: No registered users and 31 guests