Huge Repair Project

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Huge Repair Project

Now that my final exams are over, I'm going to dedicate the time I have off from school to doing water warfare stuff. The main thing will be to repair all of my broken guns, clearing that damn workbench once and for all (that is, until something else breaks).

Here's a list of everything I have to repair:

XP 75 (all I have to do is enlarge the stubs on the reservoir, probably with epoxy)

CPS 2500 (this was marauder's; it's leaking pretty badly around the nozzle area, so I'm going to open it and see what's up)

XXP 175 (I still need to make a pump for it; shouldn't be too hard.... hopefully...)

CPS 21K (going to saw open the busted valve to see what's jamming it, and this time, when I put it back together, I know not to use that damn glue that has to be heated to 400 degrees or whatever)

CPS 12K (I'm thinking of using the valve from Scott's old 2100 to replace the destroyed one that's currently in there)

I think that's about it, though if I have extra time, I might do a few more projects. Any advice is welcome, but I'm pretty sure I know what I'm doing. I'll post progress in this thread.

Here's a list of everything I have to repair:

XP 75 (all I have to do is enlarge the stubs on the reservoir, probably with epoxy)

CPS 2500 (this was marauder's; it's leaking pretty badly around the nozzle area, so I'm going to open it and see what's up)

XXP 175 (I still need to make a pump for it; shouldn't be too hard.... hopefully...)

CPS 21K (going to saw open the busted valve to see what's jamming it, and this time, when I put it back together, I know not to use that damn glue that has to be heated to 400 degrees or whatever)

CPS 12K (I'm thinking of using the valve from Scott's old 2100 to replace the destroyed one that's currently in there)

I think that's about it, though if I have extra time, I might do a few more projects. Any advice is welcome, but I'm pretty sure I know what I'm doing. I'll post progress in this thread.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

My advice is to take pictures as you progress in your repairs, and post them here.  and good luck.

and good luck.

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

Re: Huge Repair Project

Good luck!

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

Got a lot accomplished today. I made the XP 75's reservoir stubs bigger, so it doesn't blast water out the sides anymore. It's performance leaves a bit to be desired, but it still looks cool and is fun to shoot. I also sawed open the MK1 2100's valve. I have no idea what was causing it to stick, but it popped into position the second I got it open. There was nothing inside that looked like it would make the plunger stick. But anyway, I cleaned it out, lubricated it, and sealed it back together with epoxy. It's drying as I type. I also have some pictures.

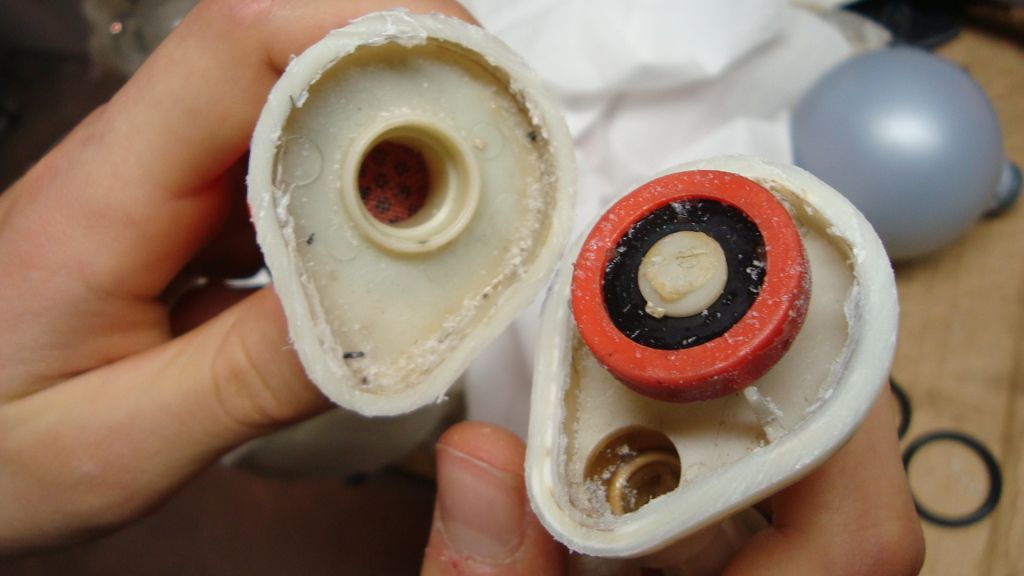

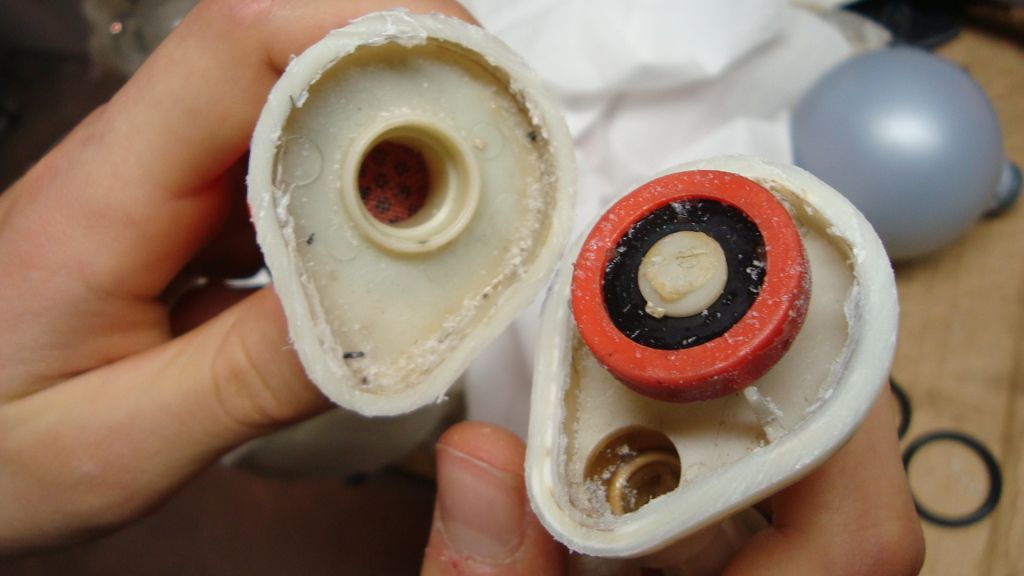

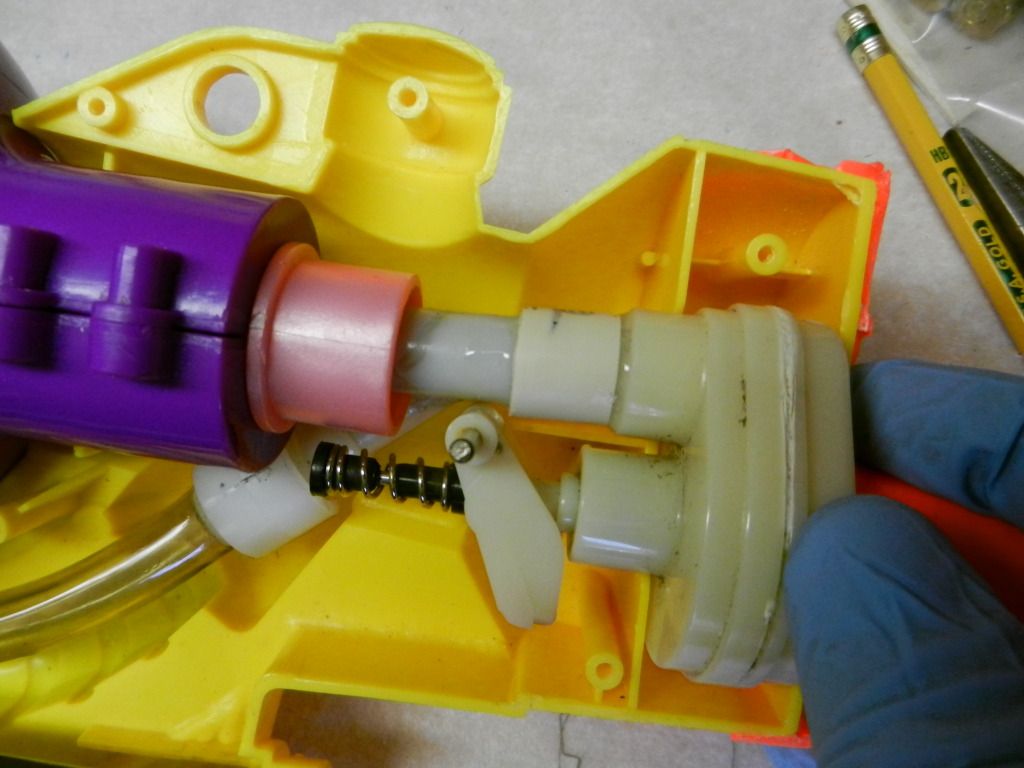

If you ever wanted to see what a 2100 MK1 valve looks like on the inside:

Cleaning out the nozzle area with a Q-tip.

The plunger section got some love too.

Here's what it looks like at the moment. Hopefully it won't turn out like my 12K valve did last year...

If that works, then I can use Scott's old MK2 valve for my 12K. If everything goes well, all I'll have left to do is make a pump for the 175, and open up the 2500 to see what the heck makes it leak so bad.

If you ever wanted to see what a 2100 MK1 valve looks like on the inside:

Cleaning out the nozzle area with a Q-tip.

The plunger section got some love too.

Here's what it looks like at the moment. Hopefully it won't turn out like my 12K valve did last year...

If that works, then I can use Scott's old MK2 valve for my 12K. If everything goes well, all I'll have left to do is make a pump for the 175, and open up the 2500 to see what the heck makes it leak so bad.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

That is awesome! Love the pics. I hope it ends up working.

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

Well, it did work for a little bit. Then when we filled it with water and after three or four pumps, a loud "POW" was heard and water started gushing out of the nozzle area. I guess the epoxy didn't work on this gun like it did on the 12K. Haven't re-opened it yet, but hopefully it's fixable.

Sometimes I really f***ing hate water guns.

Sometimes I really f***ing hate water guns.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

Well I sealed the 21K valve closed again, and this time I re-enforced it with fiberglass-impregnated epoxy. If it blows open again I'd wonder how it held together originally.

I also ran into some troubles with my MD 6000's valve. I had de-Max-D modded it earlier to stop it from pump-shooting, and it worked for a little, but then something weird happened. I'll try to explain it: When the trigger is in the 'closed' position, the valve is actually slightly open. If I pull back on the trigger, it opens up all the way, but only when the trigger is in the halfway position. Pulling the trigger all the way actually closes the valve. The only thing I can think of that could be causing this is that the ball in the valve is going too far when I pull the trigger. How the hell this could have happened is beyond me, as the lever on the valve travels the same distance as it did when the crappy mechanisim was still on it (and this problem didn't happen with my Arctic Blast). Has this happened to anybody before? And more importantly, what should I do to fix it? I probably won't re-open the gun until I finish with the 21K.

I also ran into some troubles with my MD 6000's valve. I had de-Max-D modded it earlier to stop it from pump-shooting, and it worked for a little, but then something weird happened. I'll try to explain it: When the trigger is in the 'closed' position, the valve is actually slightly open. If I pull back on the trigger, it opens up all the way, but only when the trigger is in the halfway position. Pulling the trigger all the way actually closes the valve. The only thing I can think of that could be causing this is that the ball in the valve is going too far when I pull the trigger. How the hell this could have happened is beyond me, as the lever on the valve travels the same distance as it did when the crappy mechanisim was still on it (and this problem didn't happen with my Arctic Blast). Has this happened to anybody before? And more importantly, what should I do to fix it? I probably won't re-open the gun until I finish with the 21K.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

Fiberglass impregnated epoxy????? What is that?

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

Re: Huge Repair Project

We really need to get Xplorer or Orange Mod Works or any of those Nerf metal part companies to replicate CPS pull valves that are only closed mechanically (with screws). So many fatal problems in the trigger valves could be solved this way.

marauder wrote:You have to explain things in terms that kids will understand, like videogames^ That's how I got Sam to stop using piston pumpers

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

Fiberglass-impregnated epoxy is just regular epoxy with pieces of fiberglass in it (it doesn't come like that; you have to put it in there). It makes it much stronger than normal, but it's ugly as hell, haha. Edit: And it works! The only thing is, the pump is very sticky. Anyone know a good way to lubricate it? I heard vaseline deteriorates O-rings though. Is that true?

DX: What we need is someone on here to get a 3D printer. I'd get one myself if they weren't so damn expensive. Maybe GJIV can get one if he can afford to buy ten 2000s or whatever...

So no suggestions on the 6K valve?

DX: What we need is someone on here to get a 3D printer. I'd get one myself if they weren't so damn expensive. Maybe GJIV can get one if he can afford to buy ten 2000s or whatever...

So no suggestions on the 6K valve?

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

Yes... I've been thinking about 3D printers for several months now.

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

Re: Huge Repair Project

Yeah, oil-based lube eventually degrades rubber. Use silicone grease, usually costs $2-4 for a tub/bottle.

Almost affordable - $900. We could use smaller 3D printers because we don't really need to model an entire blaster (as cool as that would be). Almost makes me want to impulse buy, but that money needs to go towards paying bills.

Almost affordable - $900. We could use smaller 3D printers because we don't really need to model an entire blaster (as cool as that would be). Almost makes me want to impulse buy, but that money needs to go towards paying bills.

marauder wrote:You have to explain things in terms that kids will understand, like videogames^ That's how I got Sam to stop using piston pumpers

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

If I was not getting married... but then again what I'm getting is worth way more than $900  so nvm

so nvm

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

Updates: Today I performed a valve transplant on my CPS 12K (I call it that even though it only has 5 balloons, haha), since the one that was in there would get stuck closed, without any way to open it (pulling back on the pin did nothing; I had to actually pull the PC off to release the pressure, resulting in water spraying everywhere). How it got like that is a long story, but when we did that "mod/repair party" at Frozen Fury, DX was going to replace the valve on his CPS 2100 MK1 that he'd sold to my brother (because it was apparently stuck open), with the valve from Scott's 2100 MK2. Unfortunately while taking the MK2 apart, my brother accidentally snapped off the valve. Nothing more could be done, but we took home some of the MK2 parts (I think Scott threw the rest of it out). Originally we were going to glue the MK2 valve back on, and replace the tubing in the MK1 with the MK2 tubing, but DX forgot to give us a pump that would fit inside the MK2 shaft (which was smaller in diameter than the MK1 shaft), so we would've had to cut the MK1 valve off and replace it with the MK2 valve.

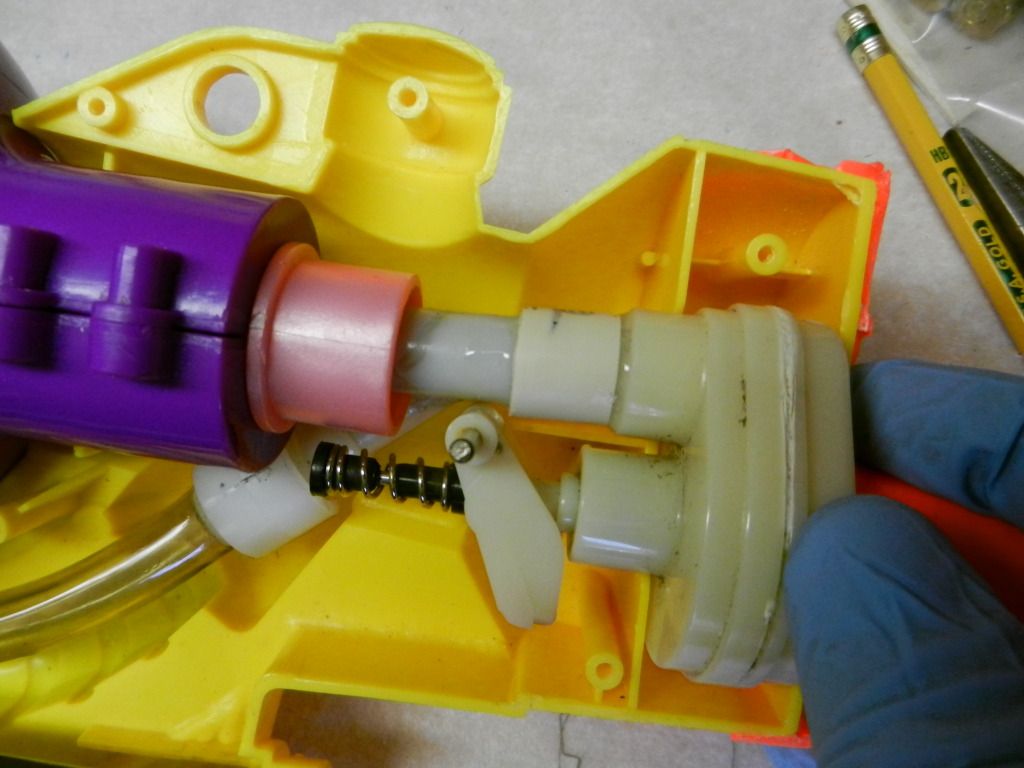

But since the MK1 valve was apparently broken anyway, I decided to saw it open to see what was jamming it. To my surprise I couldn't find anything, so I lubricated it, and sealed it back together with epoxy. It worked then, but the epoxy wasn't strong enough to hold it together, and it blew apart after a few pumps. I then re-glued it, this time using epoxy with pieces of fiberglass mixed in, to give it extra strength. On top of that I wrapped metal wires around the valve to help hold it together. That did the trick, and we now have a working MK1 21K that we measured to have an effective range of about 45 feet. Since the MK2 valve was now just sitting around, I decided to attempt to replace the faulty 12K valve with it, since it looked like the exact same part. To do this I first sawed off the destroyed valve (I'll probably use the nozzle from it for something), then made a coupler out of CPVC to hold the 2100 valve onto the 12K internals. The 12K tubing actually turned out to be slightly smaller than the 2100 tubing, so I had to hollow out the coupler more on the 12K side than on the 2100 (valve) side. After this was done I glued it, and it's drying at the moment.

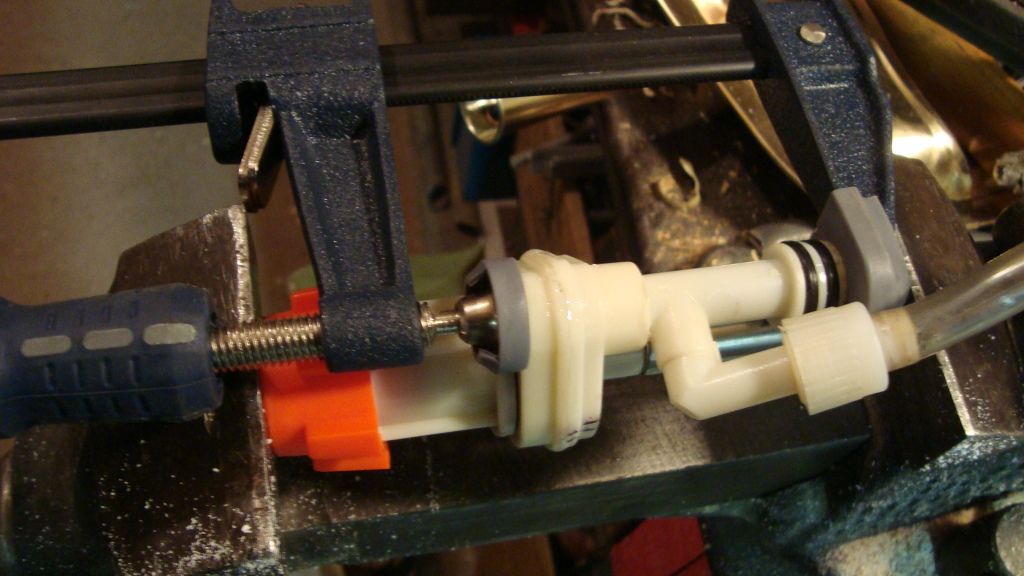

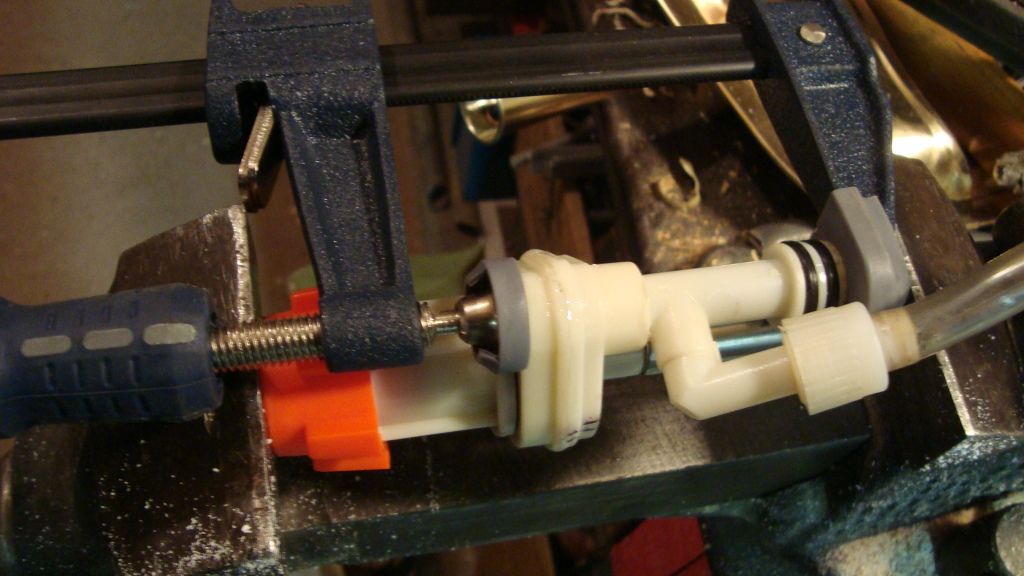

Here's a picture. Is this the first-ever known valve transplant?

If this works, then the only guns I'll have left to fix are the 175 and M4's old 2500 (or maybe my MD 2000, but I don't have much motivation to fix that). I have a few other projects planned, but they'll probably have to wait.

But since the MK1 valve was apparently broken anyway, I decided to saw it open to see what was jamming it. To my surprise I couldn't find anything, so I lubricated it, and sealed it back together with epoxy. It worked then, but the epoxy wasn't strong enough to hold it together, and it blew apart after a few pumps. I then re-glued it, this time using epoxy with pieces of fiberglass mixed in, to give it extra strength. On top of that I wrapped metal wires around the valve to help hold it together. That did the trick, and we now have a working MK1 21K that we measured to have an effective range of about 45 feet. Since the MK2 valve was now just sitting around, I decided to attempt to replace the faulty 12K valve with it, since it looked like the exact same part. To do this I first sawed off the destroyed valve (I'll probably use the nozzle from it for something), then made a coupler out of CPVC to hold the 2100 valve onto the 12K internals. The 12K tubing actually turned out to be slightly smaller than the 2100 tubing, so I had to hollow out the coupler more on the 12K side than on the 2100 (valve) side. After this was done I glued it, and it's drying at the moment.

Here's a picture. Is this the first-ever known valve transplant?

If this works, then the only guns I'll have left to fix are the 175 and M4's old 2500 (or maybe my MD 2000, but I don't have much motivation to fix that). I have a few other projects planned, but they'll probably have to wait.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

marauder

- Posts: 3975

- Joined: Tue Jul 20, 2004 9:29 pm

- Location: Charleston

- WWN League Team: Havoc

- Contact:

Re: Huge Repair Project

How's the stream lamination on that 21k?

https://hydrowar.wordpress.com/

SEAL wrote:If you ain't bloody and muddy by the end of the day, you went to a Nerf war.

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

After over a year of sitting on the workbench...

The 12K is finally fixed!

The tubing held together perfectly! I pumped it up and shot it multiple times. The biggest surprise however, was the POWER. This thing only has 5 balloons on it, but the stream is twice as thick and appears to fly farther and faster than my stock 1200. In fact, it looks even more powerful than my brother's 21K that has 30 ballooons (I tried to put 30 on the 12K at first, but the pump was almost impossible to move; I wonder if my balloons are ultra-strong or something)! The lamintation isn't all that great, but it puts out so much water that I don't think it will matter much. I've found my new medium-primary, haha. It definitely deserves the 12K title. I think I will give it a camo paintjob, because it's pretty beaten up (especially near the front, where I had to pry the nozzle cover off) anyway.

Oh, and I opened up M4's old 2500 to seek out the cause of the leak, but the only thing I could find was a tiny crack in the valve. Later I will try to shoot it without the casing so I can see where the water is coming out of.

The 12K is finally fixed!

The tubing held together perfectly! I pumped it up and shot it multiple times. The biggest surprise however, was the POWER. This thing only has 5 balloons on it, but the stream is twice as thick and appears to fly farther and faster than my stock 1200. In fact, it looks even more powerful than my brother's 21K that has 30 ballooons (I tried to put 30 on the 12K at first, but the pump was almost impossible to move; I wonder if my balloons are ultra-strong or something)! The lamintation isn't all that great, but it puts out so much water that I don't think it will matter much. I've found my new medium-primary, haha. It definitely deserves the 12K title. I think I will give it a camo paintjob, because it's pretty beaten up (especially near the front, where I had to pry the nozzle cover off) anyway.

I didn't really pay a whole lot of attention (my brother was the one shooting it), but I think it was a little worse than my stock 1200. It has great stream speed though.marauder wrote:How's the stream lamination on that 21k?

Oh, and I opened up M4's old 2500 to seek out the cause of the leak, but the only thing I could find was a tiny crack in the valve. Later I will try to shoot it without the casing so I can see where the water is coming out of.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

- SEAL

- Posts: 2537

- Joined: Thu Apr 29, 2010 11:37 am

- Location: Charlotte, NC

- WWN League Team: Catskill Mountain SEALs

- Contact:

Re: Huge Repair Project

M4, your 2500 does not leak anymore. I epoxied over the cracks in the valve, but it turned out that water was also escaping from the sides of the nozzle selector. It seems that the selector wasn't tight enough or something, and I tried multiple times to tighten it, but it didn't help. I have no idea how to fix the problem, so I just removed the thing. It actually shoots pretty far without it. It's kind of like a 2000 now, haha. So although I had to remove the ability to swich nozzles, at least water doesn't spew everywhere, and besides, I already have two 2500s with selectors.

Now the only repair job I have left to do is make a pump for the XXP 175. I've found that a length of CPVC fits in perfectly, but I'll need to find some way to plug up one end.

Now the only repair job I have left to do is make a pump for the XXP 175. I've found that a length of CPVC fits in perfectly, but I'll need to find some way to plug up one end.

~Hotel Oscar Golf~

We probably won't be back, but the legacy lives on.

We probably won't be back, but the legacy lives on.

-

soakinader

- Posts: 815

- Joined: Thu Jul 12, 2012 2:10 pm

- Location: Surrey, BC, Canada

Re: Huge Repair Project

Put a new o ring on the CPS 2500/maybe replace the spring (both). It has worked for me in the past.

My friends call me Nader. My foes just run.

Photos relocated to: https://www.flickr.com/photos/151868511 ... 8741427445

I find 'em, I fix 'em.

Photos relocated to: https://www.flickr.com/photos/151868511 ... 8741427445

I find 'em, I fix 'em.

Re: Huge Repair Project

Colors aside, the CPS 2500 is actually a CPS 2000 with a nozzle selector. It DOES have a laminator.

Who is online

Users browsing this forum: No registered users and 47 guests