Page 1 of 2

XP 70 help

Posted: Tue Apr 24, 2012 9:22 pm

by the oncoming storm

My just aquirerd 70 has a problem, it bleads water from the PC till it is up to presuser, any ideas why and how to fix it.

Re: XP 70 help

Posted: Tue Apr 24, 2012 9:44 pm

by Nitro123PG

I'm not an expert on gun repairs, but I try to help.

Where does it leak from? Directly from the PC, through the nozzle, or elsewhere. If it leaks from the nozzle, and appears to fix itself after more pumping, you probably just need to do a quick rubber band repair. If it leaks directly from the PC, I guess it some type of seal issue that I cannot fix. Otherwise, I would assume the pipe has sprung a leak, but if it stops when to full pressure like you said, that is not the case.

No matter what, you will need to open your gun to fix the problem. When it is open, pump the gun to see exactly where it leaks from, and repair accordingly.

Re: XP 70 help

Posted: Fri Apr 27, 2012 12:15 pm

by Andrew

If it leaks around where the pc meets the body of the blaster, then it may well be one of the seals. For whatever reason (it sure helps when stripping for repair though!) the internals of the XP70 are held together by the bodywork and are joined together with slip on connectors with o-ring seals.

There is one of these seals is at the base of the PC. If this o-ring has somehow been damaged, or is worn, or if there is something between the o-ring and the collar of the t-junction then it won't seal correctly. If the o-ring, or even the inside of the collar is worn, this would explain the leak disappearing when under pressure, as the PC would move upwards into a tighter spot in the collar (I could be wrong but mine seems to get slightly wider near the base of the collar) creating a tighter seal, stopping the leak.

The simplest fix would be to replace the o-ring with an identical or even slightly larger o-ring. If you are stripping it anyway, you may want to replace both o-rings at the same time as matter of course (there is an additional o-ring seal at the base of the reservoir, but this area is obviously under a lot less pressure and is less likely to leak so a new o-ring is unlikely to be required here.)

It is possible that some of the internals are damaged and are leaking, but that wouldn't explain the leak stopping when pressure builds (it would more likely be the other way round, more leak with more pressure).

It is also possible that the body of the blaster has changed shape slightly, allowing the internals to move around a bit. If this is the case some small plastic shims either side of the collar of the t-junction may help.

Hope that helps!

Re: XP 70 help

Posted: Fri Apr 27, 2012 12:48 pm

by marauder

What Andrew said is right, but I would like to add that if you have a rerelease of the XP 70 you wont have as many parts connected with O rings. The pipes will be glued together and the only O rings will be on the PC and the tank. You can see what I'm talking about here:

http://hydrowar.com/xp70.html click on the image for a larger view.

Re: XP 70 help

Posted: Sat Apr 28, 2012 5:40 am

by Andrew

Thank's M4, I didn't know that. Probably to cut down on production costs, one less o-ring connection on a lot of XP70's adds up in the end. One less place to leak aswell!

EDIT:

From what you mentioned in the 'Latest Soaker' thread it probably is the newer blue-ish XP-70 that M4 described. As mentioned by M4, you'll just have that o-ring at the base of the PC to check, there shouldn't be one on the t-junction. At least that's one less place to look!

Re: XP 70 help

Posted: Sat Apr 28, 2012 10:11 am

by the oncoming storm

Sigh no, it leaks from the noszle.

Re: XP 70 help

Posted: Sat Apr 28, 2012 11:42 am

by Andrew

Where from the nozzle? Through the actual nozzle itself or the tubing feeding the nozzle?

Re: XP 70 help

Posted: Sun Apr 29, 2012 1:14 pm

by the oncoming storm

It leaks throught the nosslze itself. Strangly it leaks ontil up to presure then stops

Re: XP 70 help

Posted: Sun Apr 29, 2012 3:12 pm

by atvan

Sounds like you just need rubber band repair.. Altnatively, G-Jiv wrote up a spring replacement guide.

Re: XP 70 help

Posted: Mon Apr 30, 2012 10:14 am

by Andrew

If it stops leaking when it reaches full pressure then atvan is probably right. As you pressurise the blaster, more force is applied to the pull valve, forcing it shut.

Details on rubber band mod

here

Can't find G-Jiv's guide yet

Re: XP 70 help

Posted: Tue May 01, 2012 8:17 pm

by the oncoming storm

Have any of you looked at XP 70 internals it has the valve and just behind it the spring, and holder. how do you replace the spring ?

Re: XP 70 help

Posted: Wed May 02, 2012 8:04 am

by Andrew

If you're talking about the small spring on the valve pin (see pic in my first post) that isn't the valve return spring. That spring makes the trigger pull progressive and smooth, and it prevents damage to the valve if you open it too quickly/too far.

The return spring is inside the valve itself. The only way to get to that spring is to open up the valve. The best person to ask about this is G-Jiv as he's replaced such springs before (still cant find the guide though!). You could always message him, I'm sure he'll be happy to guide you through it. if you don't feel confident taking the valve apart (and to be honest I wouldn't blame you) a rubber band mod can be just as effective, but is less permanent.

Re: XP 70 help

Posted: Fri May 04, 2012 3:06 pm

by the oncoming storm

Where do i add the bands?

Re: XP 70 help

Posted: Fri May 04, 2012 4:16 pm

by Andrew

Over the firng pin and around the front of the valve.

(image from

sscentral repair guide)

Re: XP 70 help

Posted: Thu May 10, 2012 9:08 pm

by the oncoming storm

The firing pin is inside the valve

Re: XP 70 help

Posted: Fri May 11, 2012 5:14 am

by atvan

That might be part of the problem.

You might have to open up the valve. Hopefully it isn't glued.

Re: XP 70 help

Posted: Fri May 11, 2012 7:55 am

by Andrew

CPS1200fann wrote:The firing pin is inside the valve

What?... How?... Wait, what? Are you sure? How did that happen?? PICS!!!

Re: XP 70 help

Posted: Thu May 17, 2012 8:55 pm

by the oncoming storm

It's made that way. the pull valve is linear.

Re: XP 70 help

Posted: Fri May 18, 2012 4:03 pm

by Andrew

The firing pin should still extend out of the back, otherwise how do you fire it?

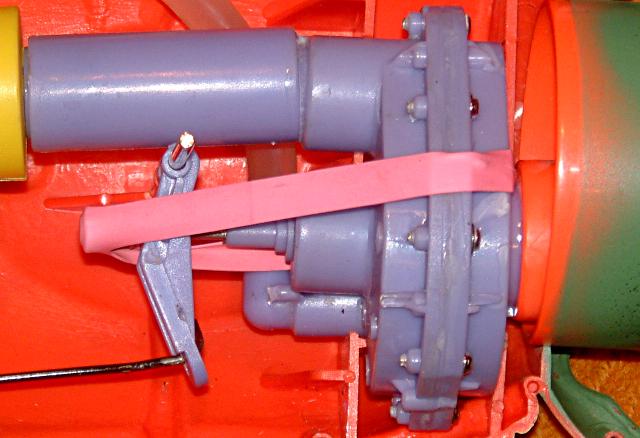

The firing pin is the long pin which comes out of the back of the valve, which is pulled by the trigger (see first XP70 pic in this thread). The elastic band has to go around the back of this pin (the black piece behind the buffer spring) to add extra force to push the firing pin (and the connected plunger inside the valve) forward to seal the valve.

The newer model is broadly the same:

(Image from

Hydrowar, hope you don't mind me using this M4)

EDIT:

For clarity, I've added a close-up pic of my XP70 valve (yes the spring's rusty, this pic was taken before I cleaned up the inside

). The yellow lines are where the elastic bands should go. You don't have to put both on, but having two elastic bands would apply an even force to the valve (up and down vectors of force cancel, so the pin isn't pulled upwards or downwards) making it last longer and operate smoothly.

Re: XP 70 help

Posted: Fri May 25, 2012 10:41 pm

by marauder

I like the 2 band idea, not sure why I hadn't thought of it before. I have no problem with anyone using my photos so long as you're not selling a gun on ebay without referencing my site. That's what pisses me off.