braincof wrote:I can almost picture what you're describing with the PVC/endcap interface but am a little bit dense/new-to-this and might need a diagram to fully grasp.

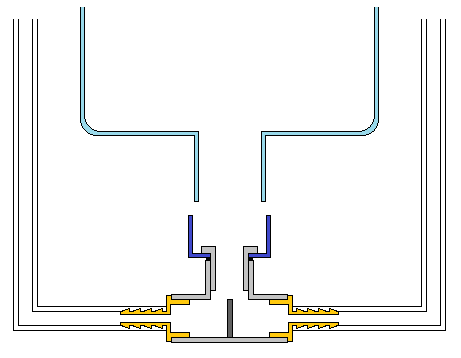

Ask and ye shall receive:

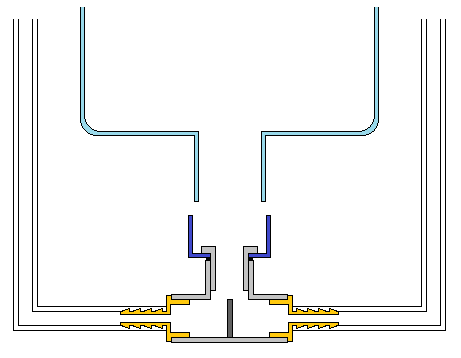

You can probably tell, that's quite a few washers and connectors (and possible areas for leaks!). Whilst drawing this diagram (and the similar one for CPS1200fann) and from reading atvan's posts on tubing barbs and threaded tees, I couldn't help thinking how over-complicated my solutions were becoming. The following drawing is simpler, should hold more pressure, should be less prone to leakage, uses up more of the liquid, and lets you have the cool bubble effect!

The dark grey piece in the threaded tee is just a plastic disc (anything waterproof will do really). You might not need this, it may only need to be smaller, or it may need to extend further into the neck of the bottle, depending on how quickly you want the liquid to be dispensed. It just 'encourages' the incoming air to travel upwards into the bottle rather than straight into the exit tubing.

The tee is (as atvan suggested) a threaded tee. I don't know exactly the size you'll need though. The barbs are threaded directly into the tee (you can use reducers if you need).

As long as the exit and entry tubing reach a point higher than the level of liquid in the bottle, the liquid will not be dispensed until the bottle has air pumped into it. The only extra thing you need is a stand of some description (two plant pots glued together with a hole in the bottom of each?) but that shouldn't be too much of a problem.