A Great Challenge of Engineering

A Great Challenge of Engineering

Okay, I'm starting an assassins game at my high school on Monday, and i was looking around and all of my beloved water guns from my small childhood have somehow disappeared. In light of this and unwillingness to go buy a new one, I have decided, as of twenty five minutes ago, to build my own. It needs to be puny, like made of a pen tube puny, and it needs to not leak (it needs to hold water for a substantial period of time as I stalk my target). So I was thinking that I'd just make a tiny pseudo stream machine deal with a pen and a tiny little plunger, then i found a crappy plastic hose nozzle with a significant amount of empty space (if i partially fill that space and pressurize it with a bike pump, amazingness could follow). I ask you, as the honorable members of WaterWar.net to please supply me with your opinions as to how to solve this predicament.

Thanks,

Chris

Thanks,

Chris

Re: A Great Challenge of Engineering

Welcome to WaterWar.net!

Interesting concept. Some crappy paint drawings would do some good for the second idea.

Small guns have limits- a design that allows more power is a small tube running down your sleave, and a power source and water on your back hidden in a backpack. At close range, a solenoid valve would be best because you could trigger the gun with a small momentary switch button, allowing more discrete activation.

San Francisco? There is at least one other member near there, you might be able to have a war with them if you are interested.

Interesting concept. Some crappy paint drawings would do some good for the second idea.

Small guns have limits- a design that allows more power is a small tube running down your sleave, and a power source and water on your back hidden in a backpack. At close range, a solenoid valve would be best because you could trigger the gun with a small momentary switch button, allowing more discrete activation.

San Francisco? There is at least one other member near there, you might be able to have a war with them if you are interested.

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

Re: A Great Challenge of Engineering

http://www.flickr.com/photos/69026434@N ... _welcome=1

i think that it's just a simple pull valve, but i 'm worried about it exploding under pressure, any thoughts?

i think that it's just a simple pull valve, but i 'm worried about it exploding under pressure, any thoughts?

Re: A Great Challenge of Engineering

Crappy range, not a good idea. There is also so little volume that it will lack enough power anyway.

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

Re: A Great Challenge of Engineering

i only need it to shoot 5-10 feet, for maybe half a second, maybe less

Re: A Great Challenge of Engineering

There is so little volume there. It is also a shape that you cannot fire concealed. There are a few assasins made homemades on SSCentral.org.

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

Re: A Great Challenge of Engineering

okay, thanks

Re: A Great Challenge of Engineering

The problem is, if you put air in that hose gun, it will rise to the top, and fire out instead of the water!

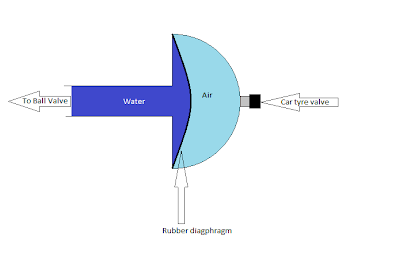

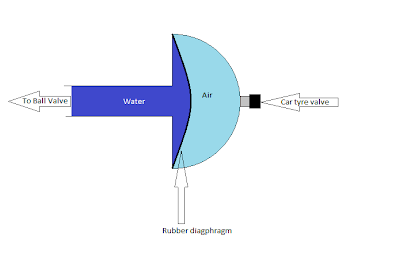

Have you considered something like this:

(approximately to scale)

It's an idea of mine for a future project at University (for assassins guild). It'll only give you one maybe two shots (but that sounds like what you want).

The white thing is a small water hammer arrestor (160ml) It has air on one side of a diaphragm and you pump water into the other. The air can be pre-pressurised (up to 8 bar on this exact model). You can pressurise it for a single shot from the water mains using the tap connector. Overall length is around 7 inches, but can be shorter if you put the small arrestor in an inside pocket with a connecting pipe (caution, if the pipe is too long, there will be A LOT of dead space and it might not work very well unless you 'bleed' the whole system first).

The tap connector nozzle may be too large to produce a good range, so you may want to use it just for filling, and switch to a smaller nozzle for firing (threaded endcaps with a small hole of about 2-4mm in the end?).

Have you considered something like this:

(approximately to scale)

It's an idea of mine for a future project at University (for assassins guild). It'll only give you one maybe two shots (but that sounds like what you want).

The white thing is a small water hammer arrestor (160ml) It has air on one side of a diaphragm and you pump water into the other. The air can be pre-pressurised (up to 8 bar on this exact model). You can pressurise it for a single shot from the water mains using the tap connector. Overall length is around 7 inches, but can be shorter if you put the small arrestor in an inside pocket with a connecting pipe (caution, if the pipe is too long, there will be A LOT of dead space and it might not work very well unless you 'bleed' the whole system first).

The tap connector nozzle may be too large to produce a good range, so you may want to use it just for filling, and switch to a smaller nozzle for firing (threaded endcaps with a small hole of about 2-4mm in the end?).

Last edited by Andrew on Sat Oct 22, 2011 5:00 pm, edited 6 times in total.

Re: A Great Challenge of Engineering

Tubing barbs make good nozzles. That is an interesting concept. Do they make slightly larger arestors? If you upped the pressure to 8 bar, I bet you could get some pretty good range.

Laminar designs are the best ergonomically too, interesting.

So, what do you think chris?

Laminar designs are the best ergonomically too, interesting.

So, what do you think chris?

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

Re: A Great Challenge of Engineering

As far as I know, that is as large as water shock arrestors go. Next size up is expansion tank level (2L) which would be too big for this purpose. There are, however, 20bar versions (but a hose would never reach that pressure anyway, and they cost 3x more than the 8bar one in the image!).

I suppose you could always carry a larger expansion tank in a backpack, and have a concealed hose running through to your sleeve, with a ball valve trigger. This could also be pressurised with the hose nozzle, but would have enough output to be able to use the hose nozzle as the firing nozzle.

Alternatively (going back to the puny size idea) a medical syringe without the needle (if the stream's too small you could drill out the nozzle a bit)? You should be able to find them in pharmacies or even garden centres (for drip feeding plants)!

I suppose you could always carry a larger expansion tank in a backpack, and have a concealed hose running through to your sleeve, with a ball valve trigger. This could also be pressurised with the hose nozzle, but would have enough output to be able to use the hose nozzle as the firing nozzle.

Alternatively (going back to the puny size idea) a medical syringe without the needle (if the stream's too small you could drill out the nozzle a bit)? You should be able to find them in pharmacies or even garden centres (for drip feeding plants)!

Re: A Great Challenge of Engineering

1. seems like a good idea, would they sell those arrestors at my local ACE hardware/plumming supply store?

2. I think understand the concept, but I don't quite understand how to fill it.

3. What kind of a hardware is required to fill the air side of the arrestor?

Thanks,

Chris

2. I think understand the concept, but I don't quite understand how to fill it.

3. What kind of a hardware is required to fill the air side of the arrestor?

Thanks,

Chris

Re: A Great Challenge of Engineering

1. I can't see why a local plumbing store wouldn't sell them. The arrestor is designed to prevent water hammer (that loud knocking noise) when you turn a tap off suddenly, by absorbing the shock of the pressure wave. I've already used a larger version on my own water gun:

2. if you use a threaded tap connector for your nozzle, like this:

you can attach a standard garden hose connector like this:

You then open the ball valve and open the valve to the garden hose (remember to CLOSE the ball valve BEFORE you remove the hose connector. 8bar pressurised water hurts at that range!). I pressurise my water gun the same way (notice the green tap connector in the picture).

3. The air side is pumped up with a car tyre pump (schrader valve)

Remember, that tap connector nozzle IS BIG. You might want to get a threaded endcap with a drilled nozzle (or threaded barb) for increased range and shot time. Also my drawing is not perfect. If you are going to get a threaded ball valve, you will need a male-male threaded adaptor to fit the tap connector nozzle.

There are also different types of arrestor, with different shapes and mechanisms (springs etc.):

These SHOULD also work, but I cannot comment as I 've never used them and I don't know their capacity. I recommend the 160ml one in the image posted earlier in this thread, as I've used it's bigger brother. Obviously the US version won't be BSP thread it'll probably be NPT (standard US).

Obviously you could use PVC instead of copper/brass fittings (smaller PVC pipe and fittings are hard to find over here).

If I'm not making much sense I apologise. It's currently very late at night in the UK, but feel free to ask if you need any more clarification. I'll try to get back to you early (for me) tomorrow (Sun 23rd) sometime.

EDIT: Blaster image update

2. if you use a threaded tap connector for your nozzle, like this:

you can attach a standard garden hose connector like this:

You then open the ball valve and open the valve to the garden hose (remember to CLOSE the ball valve BEFORE you remove the hose connector. 8bar pressurised water hurts at that range!). I pressurise my water gun the same way (notice the green tap connector in the picture).

3. The air side is pumped up with a car tyre pump (schrader valve)

Remember, that tap connector nozzle IS BIG. You might want to get a threaded endcap with a drilled nozzle (or threaded barb) for increased range and shot time. Also my drawing is not perfect. If you are going to get a threaded ball valve, you will need a male-male threaded adaptor to fit the tap connector nozzle.

There are also different types of arrestor, with different shapes and mechanisms (springs etc.):

These SHOULD also work, but I cannot comment as I 've never used them and I don't know their capacity. I recommend the 160ml one in the image posted earlier in this thread, as I've used it's bigger brother. Obviously the US version won't be BSP thread it'll probably be NPT (standard US).

Obviously you could use PVC instead of copper/brass fittings (smaller PVC pipe and fittings are hard to find over here).

If I'm not making much sense I apologise. It's currently very late at night in the UK, but feel free to ask if you need any more clarification. I'll try to get back to you early (for me) tomorrow (Sun 23rd) sometime.

EDIT: Blaster image update

Last edited by Andrew on Wed Nov 30, 2011 5:30 pm, edited 3 times in total.

Re: A Great Challenge of Engineering

you're making sense. wouldn't my garden hose die if i used it for this? wouldn't the pressure build inside the hose causing rupture and other horrible fates? what would be the capacity on one of these if i used a small one and a short pipe to the nozzle (3-4in)? I don't want to hurt anybody, is there any risk of that? lastly, one of the linear ones would work just as well, right?

Re: A Great Challenge of Engineering

As is always stated, all water guns can hurt people- if you whack them over the head. It shoud be fine. City water pressure is not amazing. Not likely to rupture a hose. Also, you can get more power and range by filling and then pumping air.

As a side not, could you please use proper grammar and organize your thoughhts into a logical order? It makes it easier for us to help you that way.

As a side not, could you please use proper grammar and organize your thoughhts into a logical order? It makes it easier for us to help you that way.

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

Re: A Great Challenge of Engineering

So for this thing I would need a piece of pvc that is a female threaded connector bit to fit the arrester and go to the ball valve?

Re: A Great Challenge of Engineering

If you can't find a threaded ball valve, then yes. But If you can find one like this:

that would be perfect, as it would connect directly to the arrestor AND the tap connector, reducing both the cost AND the length of the gun.

Then all you need is PTFE teflon tape, to seal the threads. This guide should help with that. The construction section advises on how to use teflon tape (and how much) to prevent damage, as well as how to make smaller endcap nozzles to increase range and preserve water. If you can't find a threaded ball valve then this guide on PVC cementing will ensure the seal you make is strong and will hold the pressure.

In response to your earlier question, no a 3-4" pipe will NOT increase the amount of pressurised water. Because of how the arrestor works, pressure (and thereby force) is only applied if water has entered the arrestor, and is pushing against the air. once the arrestor is empty (of water) the diaphragm rests against the outlet, and no water is forced out. Any water in tubing beyond this is 'dead' as it will not receive any force. The shorter the distance between the arrestor and the ball valve the better, as extra pipe will only increase internal friction.

Having something like this as a pressure chamber ensures that pressure dropoff is minimised, so the shot can go further for longer. Also the schrader valve allows you to adjust and find the best air pressure to balance range and shot time.

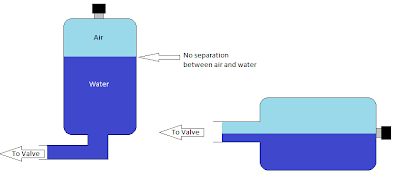

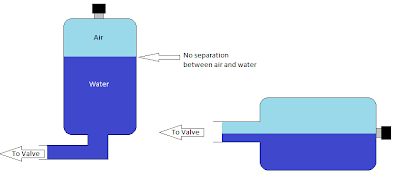

I cannot comment on whether one of the other 'linear' types will be suitable as I can't confirm if they use a diaphragm or not. if they use a spring they may work, but if they don't have either (they may just have air inside that isn't pressurised until water flows in), then you might as well just use a piece of PVC pipe, with two endcaps, at 90° to the ball valve, and stick a schrader valve on top (left image below) similar to the APH in the previous links:

Obviously this is not as ergonomic or concealable, but is necessary otherwise the air will escape (and not the water) when you open the valve (right image above). Hence my preference for a physical seperator between the air and water.

1. The separation allows firing at any angle, without mist shots (air escaping).

2. Such devices only need to be precharged once (air doesn't escape at the end of a shot unlike the image above left).

Also, as atvan said, hose pressure is perfectly safe for this. I pressurise my homemade the same way (through the bottom tap connector QFD-style). Remember, if the pressure in the chamber is ABOVE water mains pressure, it won't fill the chamber anyway, and if it doesn't fill the chamber, then the air cannot exert it's force! The arrestors are normally pre-pressurised at 3.5 bar. Reduce it to 3 or even 2.75 bar, and you can fill the chamber. If necessary you can then pump more air in through the schrader valve, after you've filled the arrestor with water (but you will have to reduce it before you can refill it with water, or you'll have an almost empty tank when you need it most!).

EDIT: Updated due to blaster development

that would be perfect, as it would connect directly to the arrestor AND the tap connector, reducing both the cost AND the length of the gun.

Then all you need is PTFE teflon tape, to seal the threads. This guide should help with that. The construction section advises on how to use teflon tape (and how much) to prevent damage, as well as how to make smaller endcap nozzles to increase range and preserve water. If you can't find a threaded ball valve then this guide on PVC cementing will ensure the seal you make is strong and will hold the pressure.

In response to your earlier question, no a 3-4" pipe will NOT increase the amount of pressurised water. Because of how the arrestor works, pressure (and thereby force) is only applied if water has entered the arrestor, and is pushing against the air. once the arrestor is empty (of water) the diaphragm rests against the outlet, and no water is forced out. Any water in tubing beyond this is 'dead' as it will not receive any force. The shorter the distance between the arrestor and the ball valve the better, as extra pipe will only increase internal friction.

Having something like this as a pressure chamber ensures that pressure dropoff is minimised, so the shot can go further for longer. Also the schrader valve allows you to adjust and find the best air pressure to balance range and shot time.

I cannot comment on whether one of the other 'linear' types will be suitable as I can't confirm if they use a diaphragm or not. if they use a spring they may work, but if they don't have either (they may just have air inside that isn't pressurised until water flows in), then you might as well just use a piece of PVC pipe, with two endcaps, at 90° to the ball valve, and stick a schrader valve on top (left image below) similar to the APH in the previous links:

Obviously this is not as ergonomic or concealable, but is necessary otherwise the air will escape (and not the water) when you open the valve (right image above). Hence my preference for a physical seperator between the air and water.

1. The separation allows firing at any angle, without mist shots (air escaping).

2. Such devices only need to be precharged once (air doesn't escape at the end of a shot unlike the image above left).

Also, as atvan said, hose pressure is perfectly safe for this. I pressurise my homemade the same way (through the bottom tap connector QFD-style). Remember, if the pressure in the chamber is ABOVE water mains pressure, it won't fill the chamber anyway, and if it doesn't fill the chamber, then the air cannot exert it's force! The arrestors are normally pre-pressurised at 3.5 bar. Reduce it to 3 or even 2.75 bar, and you can fill the chamber. If necessary you can then pump more air in through the schrader valve, after you've filled the arrestor with water (but you will have to reduce it before you can refill it with water, or you'll have an almost empty tank when you need it most!).

EDIT: Updated due to blaster development

Last edited by Andrew on Thu Nov 17, 2011 11:33 am, edited 2 times in total.

Re: A Great Challenge of Engineering

cool, i'll get to work on that and hopefully post some pics when i'm done

Re: A Great Challenge of Engineering

Good luck!

DX wrote:In the neanderthal days of K-modding, people would lop off the whole PRV

Beware the PurpleWell, not that much soakage.

- martianshark

- Posts: 1026

- Joined: Mon Mar 08, 2010 11:32 pm

- Location: Mars, CA

Re: A Great Challenge of Engineering

That's awesome. I didn't know you could buy a pre-made diaphragm thing. I kind of doubt it's available in stores though; It's probably not a very wanted part, and considering how small Ace Hardware usually is, they probably wouldn't have enough room for parts like this that aren't very necessary.

CA99 wrote:It's funny because you can get 5 water bottles and a pencil for much less than $90.

Re: A Great Challenge of Engineering

i have a pretty big ACE down the street from me, ill check there tomorrow

Who is online

Users browsing this forum: No registered users and 16 guests