You could, possibly, make the first half of it (from the nozzle up to where the arrestor connects) first, and buy a linear type to test with. If it doesn't work well (as long as you don't damage the packaging, and you dry it out first) you should be able to get a refund saying it is unsuitable for what you need (once again DON'T tell them what you needed it for, they'll assume you'll use it for it's intended purpose).

If you think it will be too expensive, and because time is no longer of the essence, you could try and make you're own pressure chamber.

Perhaps along the lines of SEAl's SCH

Here and

Here just use 1/2" pipe istead of 3/4", and a smaller pressure chamber and it'll be a bit more compact!. if you put a 1/2" male thread on the bottom of the PVC pressure chamber, you can unscrew it later, and fit a smaller diaphragm arrestor!

Or even a mini version of

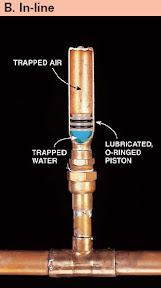

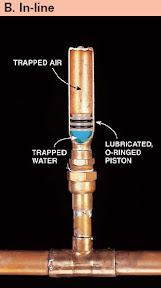

Supercannon II (a piston separates the air and water, like the linear arrestor) but use narrower pipe for the pressure chamber. Again, a 1/2" male thread on the water side of the chamber, and you can swap it out later (although, if you can make this one work, there will be no need for the diaphragm arrestor).

Put a schrader valve in the top of the SCH or on the airside end of the mini Supercannon, and you can pre-charge them easily!

You can always convert it to the curent design when funding allows you to!